Autumn 2015 | |

A new work-horse for the woodland. |  |

The compost loo gets a roof. Larch roofing battens and cedar shingles. |  The roof complete. |

Summer 2015 | |

Spoon-making at Sallerton Wood. |  A wet day working in the woods. |

The compost loo gets roof timbers. |  Cladding the compost loo with sawn Ash. |

A recently-found source of clay in the Wood. Suitable for making a timber-drying kiln maybe? |  The next stage for the compost loo - Larch timber frame completed and erected ready for cladding. |

Prepared Hazel bars and Ash rails for a hurdle. |  The completed hurdle in position to keep young Thomas away from the log-burner area at home. |

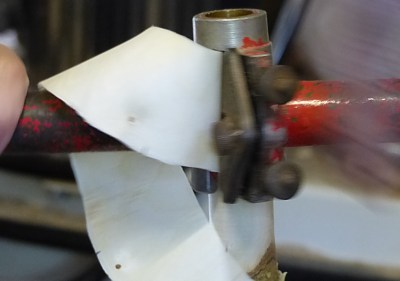

Ash and Hazel poles for making a hurdle. |  Shaping the ends of the bars with a rounder. |

Ivy removed from useful Ash coppice trees. |  Track-grading near the entrance. |

The completed well. |  Spring-water on tap, piped to near the woodland workshop. |

A spring; a useful source of naturally-filtered water. |  Captured spring. |

A new gate for the entrance, made at Sallerton Wood from timber extracted and processed there. | |

Spring 2015 | |

Woodland shelter frame complete with its tarpaulin roof. | |

Cutting the surplus off the pegs. | |

Erecting the trusses. |  The assembled frame. |

Early stages of erection of the woodland shelter frame. |  Checking levels. |

Frame joint cutting. |  Frame peg making with a draw-knife and shaving-horse. |

Prepared timber for a woodland shelter frame. | |

Preparing timber for a timber frame with the chainsaw mill. | |

Moving materials the hard way. |  This will make life easier! |

Coppiced timber stacked to dry. |  Newly-planted native broadleaved tree saplings. |